FEATURES

For mounting heights to 16′ (environmental separation) and 14′ (insect control).

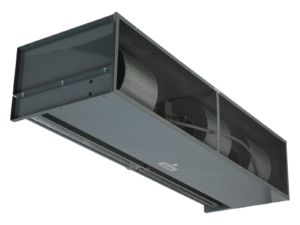

The Berner Hazardous Location Series 16 Air Curtain is designed and manufactured to comply with ANSI/NFPA-70 National Electrical Code (NEC) for Electrical Equipment: Class I, Division 1 and 2, Groups C and D for gases.

- Used in areas where gases may create a hazardous situation to keep temperatures stable and flying insects out when the doors are open.

- Engineered to perform and built to last

- Simple to install, operate, and maintain

- Made in U.S.A.

Available in single lengths from 5′ to 16′

AMBIENT

- Constructed for Class I, Division 1 & 2, Groups C & D

- 21″ high x 34″ deep

- Explosion-proof single-speed motor(s) temperature code T3C

- Interior and exterior gray zinc epoxy powder-coated aluminized steel cabinet with aluminized steel expanded metal screen

- Split cabinet construction for fan assembly removal

- External Mount Explosion Proof Junction Box (one per motor)

- Aluminum impellers in a matching housing

- Top and bottom mounting

- High efficiency Pro-V Nozzle

STEAM/HOT WATER HEAT

- Constructed for Class I, Division 1 & 2, Groups C & D

- 21″ high x 34″ deep

- Explosion-proof single-speed motor(s) temperature code T3C

- Interior and exterior gray zinc epoxy powder-coated aluminized steel cabinet with aluminized steel expanded metal screen

- Split cabinet construction for fan assembly removal

- External Mount Explosion Proof Junction Box (one per motor)

- Aluminum impellers in a matching housing

- Top and bottom mounting

- High efficiency Pro-V Nozzle

Coil features:

- Aluminum casing

- 5/8″ copper tube X .035″ wall

- Aluminum fins

- Leak tested at 450 psi

Accessories

Control Panels

Three-Phase Control Panels:

All three-phase power supplies require a three-phase control panel, remote (standard) or factory mounted, and an activation switch.

Standard Control Panel Construction:

Hazardous Location

- UL Classified NEMA 7 & 9 Aluminum Enclosure for Use in Class I, Division 1 & 2, Groups C & D Applications

- IEC Style Contactor, Solid State Adjustable Motor Overload(s), Control Transformer w/ Primary and Secondary Fusing (120V Control Voltage), Fusing (as required), Terminal Strip, and Time Delay or 24V Control (as required)

Standard Control Panel Construction:

Non-hazardous Location

- NEMA 4/12 Enclosure, Motor Contactor (factory wired), Motor Overload(s), 120 V Control Transformer, and Time Delay or 24 V Control (as required)

- Optional control panel enclosure constructions: poly fiberglass, aluminum, stainless steel

Control Panel Accessories

Hazardous Location

- Hand/off/automatic switches

- Start/stop push button(s)

- 24 V control

- Time delay

Non-Hazardous Location

- Disconnect switch(es) — toggle disconnects based on number of power supplies required

Electrical Accessories

Hazardous Location

- Door switches: side plunger style

- Hand/off/automatic switches

- Start/stop push button(s)

- Remote thermostat

Mechanical Accessories

- Wall support brackets

- 12″ extension brackets

- 2″ washable aluminum filters with frame