What is an Air Curtain?

An air curtain, also known as an air door, is a machine that blows a controlled stream of air across an opening to the other side to create an air seal. This seal separates different environments while allowing a smooth, uninterrupted flow of traffic and unobstructed vision through the opening. Because they help to contain heated or conditioned air, they provide sizable energy savings and increased personal comfort when applied in industrial or commercial settings. They also help to stop the infiltration of pollutants and flying insects.

How Does an Air Curtain Work?

- Once it is powered on, air is brought into the unit through the intake

- The air then enters the fan housing and is accelerated by the fan.

- This fast-moving air goes into a plenum, which allows for an even distribution of air along the full length of the discharge nozzle.

- Airfoil-shaped vanes in the nozzle create a uniform air stream with minimal turbulence.

- The air discharged through the nozzle creates a jet stream to the floor. Approximately 80% of the air returns to the intake side of the air curtain, and 20% goes in the opposite direction.

Why Use an Air Curtain?

- Energy savings through control of air transfer

- Energy savings due to shorter run times of air handler or compressor

- Safe environment support by increasing ventilation and de-stratifying the air

- Maintain employee/customer comfort

- Reduce flying insect infiltration

- Unhindered traffic flow & unobstructed visibility across the threshold

- Increase productivity due to stable temperatures

- Maintain usable space around the door

- Elimination of ice and fog in cold storage areas

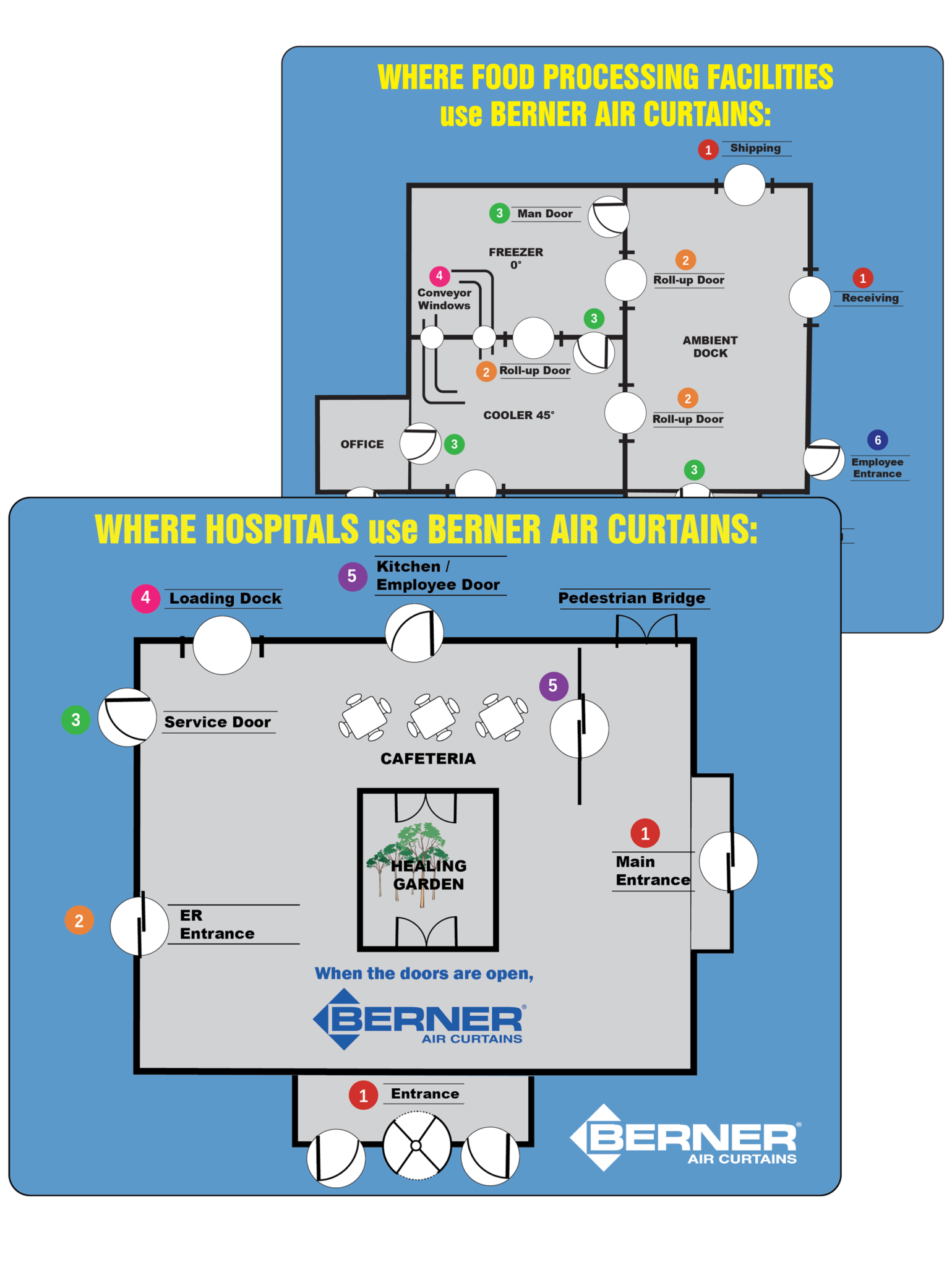

Where to Use an Air Curtain?

Follow the links below to find out more about the different locations within each building type that could benefit from an air curtain installation.

Do Air Curtains Really Work?

Yes! Air curtains, a.k.a. air doors or fly fans, properly selected, installed and operated really do work to create a barrier out of air across an opening. So much so, that ASHRAE Standard 90.1-2019 and the International Energy Conservation Code (IECC) building code allows AMCA certified air curtains as alternatives to vestibules.

Do Air Curtains Keep Flies Out?

Yes! And mosquitos, yellowjackets, and bees. Air curtains, sometimes referred to as fly fans, supply a high velocity stream of air across a door or window opening that keeps pests like insects from entering the building. These flies and other small insects, find the air stream too powerful for them to fly through and if they try, they are blown down or sideways before they can enter the building.

Do Air Curtains Cool a Room?

While air curtains are not the same as air conditioners, they are highly effective at maintaining the interior temperature, keeping cool air inside and warm air outside (or vice versa) when the door is open. They are sometimes referred to as “invisible doors” as they create an invisible barrier between inside and outside environments. Because they help to contain heated or conditioned air, they provide sizable energy savings and increased personal comfort when applied in industrial or commercial settings.

How Much Does an Air Curtain Cost?

Air curtains can range in price depending on features, the application, and specific requirements. Consult a Berner sales rep today to get pricing on a model and control package that is best suited for your project.

Continuing Education

Find out more about Berner Air Curtains by choosing a topic below:

Free Credited Courses:

AEC Daily continuing education course online: “Air Curtains: Energy Savings & Occupant Comfort.”

*This is an approved AIA course (1.25 LU/HSW hour), and it also qualifies for GBCI, RCEP, and many other organizations’ continuing education (CEU) requirements. Under USGBC rule, it qualifies as a 1.0 CE hour.

Are you an FCSI member? Download this “Air Curtains: Energy Savings & Occupant Comfort” training for 1.0 FCSI approved continuing education credit hour.

AMCA insite Webinar – Air Curtains: Energy Codes & Standards

*Earn 1.0 PDH credit by viewing the entire webinar and completing the online survey here. Credits will be issued electronically within 30 days of completion.